-

Guxiang Town, Chaozhou City,Guangdong Province, China

Porcelain Toilet Glazing Explained: Why 1280°C Firing is Important

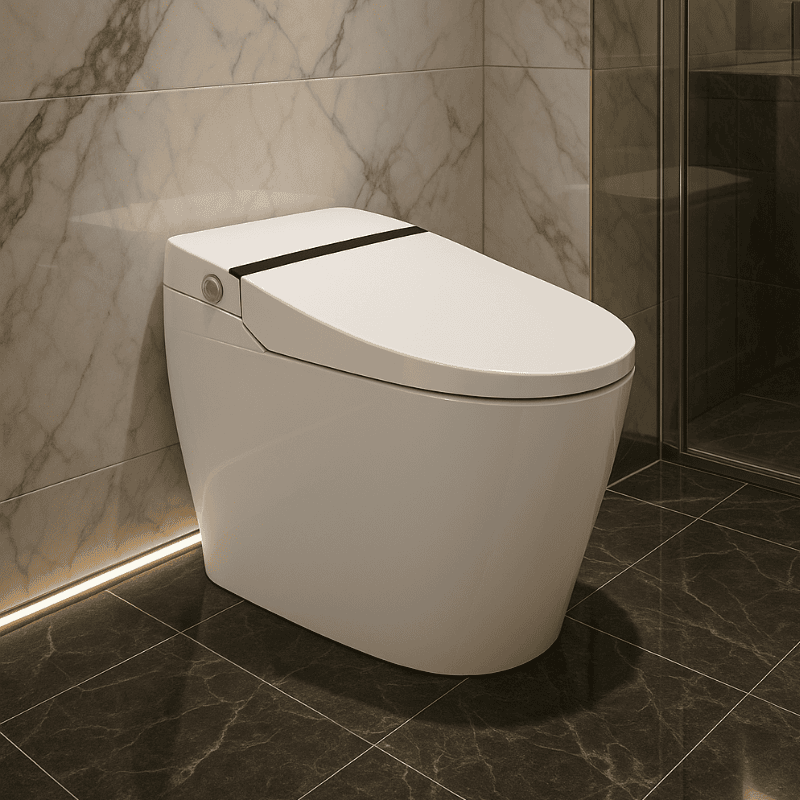

Porcelain Toilet Glazing: What It Is, How It Works, and Why It Matters

When people shop for a toilet, they usually compare design, flushing power, or smart features.

Very few ask the most important question.

How well is it glazed?

Porcelain toilet glazing plays a quiet but critical role in hygiene, durability, and long-term performance. It’s the difference between a toilet that still looks clean after ten years and one that stains, smells, or cracks far too soon.

In this article, I’ll walk you through the glazing process step by step—using real manufacturing principles, not marketing buzzwords—so you understand what actually makes a toilet high quality.

What Is Porcelain Toilet Glazing?

Porcelain toilet glazing is the process of applying a liquid glass coating to the surface of a porcelain toilet before it is fired in a kiln.

Once fired at very high temperatures, the glaze:

- Melts

- Bonds with the ceramic body

- Forms a smooth, sealed surface

This glass-like layer is what you touch when you sit on a toilet.

It’s also what protects the porcelain underneath.

Without proper glazing, porcelain remains porous. That means it can absorb:

- Water

- Bacteria

- Odors

- Stains

Good glazing closes those pores.

A Short History of Porcelain Glazing (Why Tradition Still Matters)

Porcelain glazing is not new.

Its roots go back hundreds of years, especially to Jingdezhen, China, often called the “porcelain capital of the world.” Historical records show that high-temperature firing techniques were already refined during the Ming and Qing dynasties.

According to ceramic history studies summarized by Stanford’s Open Virtual Assistant Lab, the same principles used in fine porcelain centuries ago still apply to modern sanitary ware today.

What changed is:

- Kiln precision

- Material consistency

- Quality control

The science improved, but the fundamentals stayed the same.

The Core Materials Behind Porcelain Toilet Glazing

High-quality glazing starts with the right materials.

1. Clay

Clay provides plasticity.

It allows the toilet body to be shaped before firing.

The type and purity of clay directly affect final strength.

2. Feldspar

Feldspar is a flux.

It lowers the melting point and helps materials fuse during firing.

According to Digitalfire (digitalfire.com), feldspar content strongly influences glaze smoothness and vitrification.

3. Silica and Quartz

Silica forms the glassy phase of porcelain.

Quartz adds rigidity and structural stability.

4. Additional Additives

Some manufacturers include:

- Zirconium silicate for whiteness and opacity

- Aluminum oxide for hardness

- Grog (recycled porcelain) to reduce shrinkage

Each ingredient plays a role in durability and surface quality.

What “High-Temperature Firing” Really Means

Not all porcelain is fired the same way.

For premium sanitary ware, firing temperatures typically reach 1280°C.

At this temperature, something important happens.

Vitrification

Vitrification is when:

- Clay particles fuse together

- Pores shrink and close

- The body becomes dense and non-porous

This is the foundation of strong porcelain.

According to ceramic manufacturing research summarized by Holst Porzellan

(holst-porzellan.com), vitrified porcelain absorbs far less water than low-fired ceramics.

Less absorption means better hygiene and longer life.

The Firing Process Explained

High-quality porcelain toilets use high temperature firing.

- Melts the glaze

- Bonds glaze to porcelain

- Achieves final surface finish

This method offers better control and fewer defects. Most importantly, it improves water absorption rate.

Why Controlled Cooling Is Just as Important

Firing doesn’t end when the kiln shuts off.

Cooling must be carefully managed.

If cooling happens too fast:

- Thermal shock can occur

- Micro-cracks form

- Long-term durability suffers

Manufacturers often cool slowly down to around 500°C before accelerating the process.

Some even use annealing to release internal stress.

This step is invisible to buyers—but critical.

Types of Glazes Used in Toilet Manufacturing

Understanding glaze types helps explain price differences.

By Firing Temperature

Low-Temperature Glazes (<1000°C)

- Bright colors

- Higher porosity

- Not ideal for toilets

High-Temperature Glazes (>1280°C)

- Strongest

- Smoothest

- Best stain resistance

According to ceramic glaze studies referenced by storm.genie.stanford.edu, high-temperature glazes are the most suitable for sanitary ware.

Glossy vs. Matte Glaze: Why Toilets Use Glossy

Glossy glaze is standard for toilets—and for good reason.

Glossy surfaces:

- Are easier to clean

- Reflect light better

- Resist residue buildup

Matte glazes look stylish but are harder to maintain in wet, high-hygiene environments.

For toilets, practicality wins.

Trapway Glazing: The Hidden Detail Most Buyers Miss

The trapway is the internal channel waste travels through.

If it’s poorly glazed:

- Waste sticks

- Odors linger

- Clogs happen more often

High-end toilets fully glaze the trapway using specialized techniques.

This is especially important for advanced flushing systems, such as those used in the CL-616 P-trap Smart Toilet for Europe, where smooth internal surfaces directly affect performance.

Hygiene Benefits of High-Quality Glazing

Porcelain toilet glazing has a direct impact on cleanliness.

A dense, non-porous glaze:

- Prevents bacteria from settling

- Reduces odor absorption

- Makes daily cleaning easier

Studies cited by ceramic research platforms show that vitrified porcelain surfaces harbor fewer microbes than porous ceramics.

This is why hospitals and commercial facilities insist on high-quality glaze standards.

Durability: What Happens After Years of Use?

A well-glazed toilet:

- Keeps its color

- Resists scratches

- Maintains structural integrity

Poor glazing leads to:

- Yellowing

- Surface crazing

- Stain penetration

Once the glaze fails, repair is almost impossible.

Replacement becomes the only option.

Porcelain Toilet Glazing and Smart Toilets

Smart toilets place higher demands on ceramic quality.

Why?

Because:

- Heating elements

- Sensors

- Strong flushing systems

All rely on stable porcelain.

That’s why models like the CL-640 Smart Toilet with Foam Shield are built on fully vitrified porcelain bodies.

Technology only works when the foundation is solid.

Manufacturing Challenges and Quality Control

Producing high-quality glazed porcelain is not easy.

Manufacturers must manage:

- Raw material consistency

- Humidity during drying

- Precise firing schedules

- Glaze thickness

According to ceramic production studies summarized by Standarford Lab, even small variations can cause defects like:

- Cracking

- Uneven glaze

- Weak bonding

Strict quality control is essential.

Environmental Considerations

High-temperature firing consumes energy.

That’s a real concern.

But there’s another side.

Long-lasting toilets:

- Reduce replacement frequency

- Lower material waste

- Offer better lifetime efficiency

Some manufacturers are now improving kiln efficiency and heat recovery to reduce environmental impact.

Durability itself is a form of sustainability.

How to Identify a Well-Glazed Toilet

Here’s what you can check:

- Even, deep gloss

- Smooth surface inside and out

- Fully glazed trapway

- Manufacturer transparency about firing temperature

If a brand openly states high-temperature firing, that’s usually a good sign.

FAQ: Porcelain Toilet Glazing

FAQ: Porcelain Toilet Glazing

Q1. Is porcelain better than ceramic?

Q2. Does glaze wear off?

Q3. Can glaze prevent stains completely?

Q4. Is high-temperature firing worth the cost?

Q1. Is porcelain better than ceramic?

Yes. Porcelain is fired at higher temperatures and is denser.

Q2. Does glaze wear off?

High-quality glaze does not wear off under normal use.

Q3. Can glaze prevent stains completely?

No surface is perfect, but good glazing makes stains far less likely.

Q4. Is high-temperature firing worth the cost?

For long-term performance and hygiene, yes.

Final Thoughts

Porcelain toilet glazing isn’t a marketing term.

It’s real manufacturing science.

If you care about hygiene, durability, and long-term value, glazing quality matters just as much as smart features or flushing power.

A smart toilet is only as good as the porcelain beneath it.